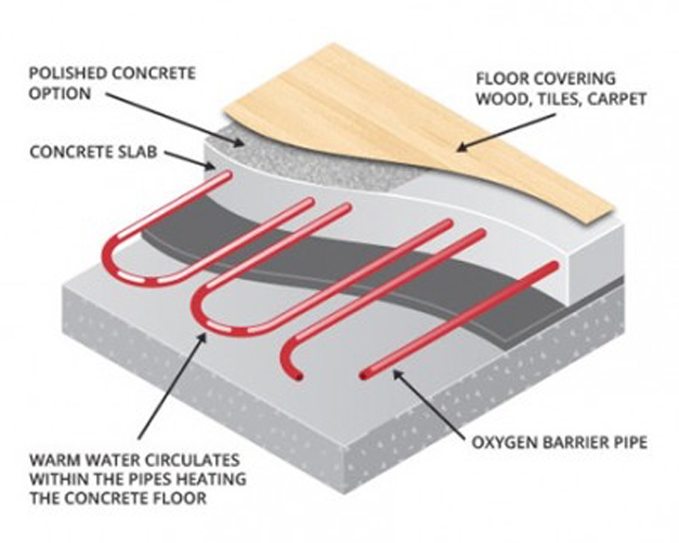

Underfloor hydronic heating is quickly becoming the desired choice as it is relatively clean, cost-effective and can heat a whole room or house evenly.

Buildings that are used a lot have other heat sources or have low heat loss are ideal.

Homes, schools, offices, churches, business showrooms, aviaries and horticulture rooms are all perfect examples of areas that would benefit from a floor heating system.

Heating the room or building evenly and with little to no maintenance is a massive benefit. You also gain extra space in your rooms because all your heating is under the floor, rather than in a boiler room or a clunky radiator sitting in the corner of the house.

As everything is underneath the floor, you have complete freedom to design your room exactly the way you want.

Each room can be individually controlled using our extensive range of electronic controls and thermostats.

When purchasing a full system from Norwest Gas heating, you are guaranteed quality equipment and workmanship.

Norwest Gas can supply and install underfloor heating solutions to domestic and commercial applications including childcare centres, aged care facilities, motels, hospitals, office blocks, restaurants etc.

It is recommended that hydronic heating (underfloor and/or radiators) is serviced annually to ensure optimal performance and efficiency.

Yes, it can be installed in an existing home, this is usually performed when the flooring is being upgraded/changed. The installation would need to be performed prior to the new flooring being chosen and installed. If thinking about a new floor and wanting to heat, contact us today and we can assist you in your needs.

The base body of the push-fit fitting and the fixing ring is made of high-performance PPSU, which is resistant to high temperatures, corrosion and encrustation. The caps are produced in glass fibre reinforced polyamide. The extremely high notched impact strength and lack of sensitivity to stress cracks make the fitting robust and insensitive to impacts.

This fitting is made of advanced PPSU (polyphenylsulfone) plastic material. High temperature and pressure resistance, high strength and suitability for its use with particularly aggressive water are the key advantages of this type of fitting.

The M1 metal press fitting is resistant to high temperatures, corrosion and encrustation. Equipped with a fixed stainless steel press sleeve which gives the connection additional strength and reliability. The M1 fitting has an observation window, through which the insert depth of the pipe can be reliably checked before pressing.

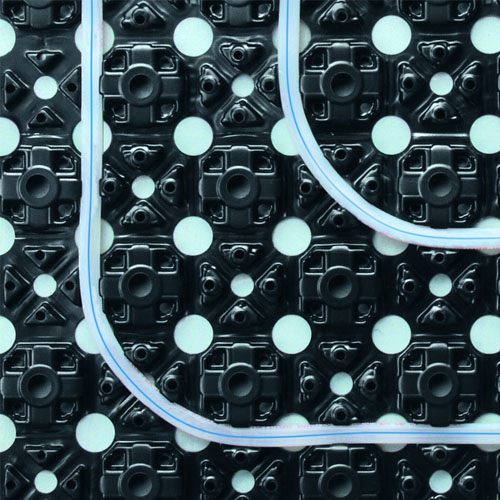

This market-leading pre-formed panel with an R 1.0 value is used for insulating and support of underfloor heating pipes, essential for creating a modern and energy-efficient system.

A European plastic modular manifold developed and designed with control valves for every circuit, lower installation depth and the ultimate in versatility.

European Pex-A made from crosslink polyethylene pipe with an oxygen diffusion layer of EVOH.

Elektra electric under-tile heating mats are manufactured using thin heating cable securely fixed to a 500mm wide glass fibre mesh to aid installation, and come in a range of lengths, making them suitable for all room sizes, floor refurbishments or new builds.

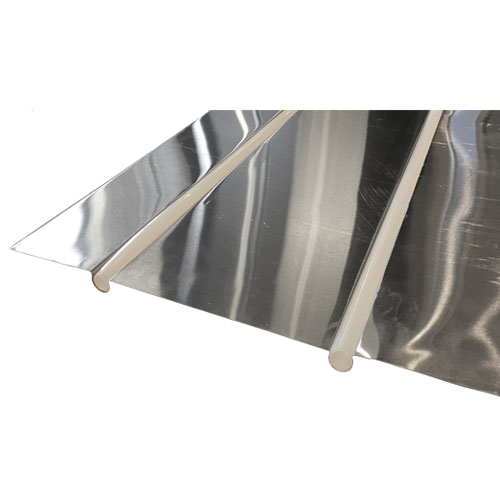

Aluminium Heat Emission Plates are used to facilitate suspended floor heating. Secured to joists, battens or directly under timber floorboards, heat emission plates will maximise the heat transfer area of underfloor heating pipe running its length.

With minimum overall depth, Uponor Minitec is an ideal system for renovation projects. The Uponor Minitec sheeting element with specialised PEX-A pipes measuring 9.9 x 1.1 mm, is easy to lay on the existing screed. The adhesive layer on the back of the sheet guarantees a secure bond during installation. The levelling layer is installed just above the raised knuckles, resulting in an increase in floor height of only 15 mm.

Work at the highest level with European multi-layer composite pipe systems available with brass crimp, ppsu crimp and smartfix push-fit fittings for complete versatility

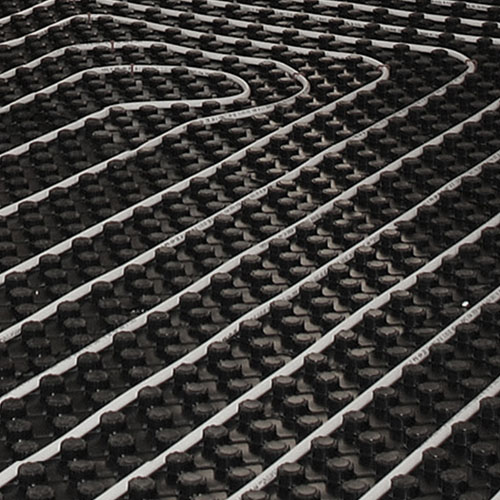

Hurlcon Hydronic Heating’s Australian made studded polystyrene insulation panels are perfect for installing a hydronic screed heating system over your structural slab or existing floor. The 1200mm x 800mm panels interlock around each edge to make installing fast and straightforward while still providing a seamless and robust base to work on. The AluPex or Copex pipe is inserted between the studs and held firmly in place, with staples only required to secure the tight bends. The expanded polystyrene is high-density, flame retardant and 100% recyclable, and can be cut with a handsaw or knife, and the 30mm base thickness gives excellent insulation against downward heat losses. The studs are capable of securing pipes up to 20mm diameter.

The PM100 control unit from Giacomini is designed to be used in conjunction with manifold systems and is capable of controlling up to 8 ambient room thermostats driving up to 16 actuators.

SBK’s Twinco 3000 manifold station offers a solution for a combined underfloor/radiator heating system for comfort and flexibility. SBK offer a 5 year warranty against manufacturing defects.

Capricorn has the solution to keeping manifolds safe and tidy with their durable and practical powder-coated cabinets. For more details, please download the brochure below.

The German designed and manufactured SBK modular manifold system is comprised of individual ‘blocks’ which can easily be assembled to the required number of heating circuits and allows for fast on-site alteration to circuit numbers as well. Blocks are coloured coded for flow (Red) and return (Blue) piping, and are available as plain blocks or with flow control valves and flow meters. Flow control valves can be quickly removed to allow for thermal actuators in zone controlled systems, and the SBK patented flow meter allows for easy and accurate flow adjustment. Constructed from glass reinforced plastic with a multi-chamber design, the manifold blocks are corrosion resistant and have inbuilt insulating properties. This means significantly reduced heat losses for heating systems and less risk of condensation in cooling systems. The individual blocks are reversible, allowing pipe circuits to be directed upwards if required, and the internal geometry results in a minimum pressure drop through the manifold system. SBK offer a 5-year warranty against manufacturing defects.

SBK’s German engineers have developed the ingenious Multizone system 3000 which allows you to control 2-3 zones from one actuator, giving greater flexibility with zoning, as well as significant cost savings. SBK offer a 5-year warranty against manufacturing defects.

Capricorn’s, durable and long-lasting complete 1″ stainless steel manifolds are for floor heating.

Oventrop Copex pipe is used for in-slab hydronic underfloor heating systems. Manufactured from high-density polyethylene Oventrop Copex is cross-linked under high temperatures to give a highly resilient yet extremely flexible pipe. It is highly resistant to chemicals and has a working temperature range of -20 deg to 90 deg C at pressures well above typical operating pressure. The smooth bore of Oventrop Copex pipes prevent sedimentation and flow loss over time. Copex has an EVOH oxygen barrier protected under the highly resilient outer PEX-Xc layer. The lightweight, strength and flexibility of Oventrop Copex pipe make installation of hydronic underfloor heating systems fast and easy.

N.T.M. S.P.A. is a leading Italian manufacturer of fittings and markets its products in Italy and more than 50 foreign countries. Relocated to Brandico (also in the province of Brescia) at the end of 2004, it now operates a 10,000 square meter facility. N.T.M. S.P.A. is a continually growing company with a production capacity of 200,000 fittings a day. The name N.T.M. S.P.A. derives from the name of its founder, Mario Tripoli, who, along with the management team at N.T.M. S.P.A., has 30 years of experience in the design and manufacture of brass fittings. N.T.M. S.P.A. profits from his extensive know-how, carrying on the best tradition in the industry and guaranteeing its customers maximum quality and next-generation product ideas coupled with state-of-the-art technologies.

Hurlcon Hydronic Heating’s AluPex multilayer pipe is manufactured from a core of high-density polyethylene, a mid-layer of aluminium foil, and an outer coating of high-density polyethylene. These layers are bonded together with two adhesive layers. The combination of polyethylene layers gives an extremely strong and resilient pipe with excellent flexibility when required. The aluminium layer allows the pipe to hold its shape when formed into a radius, significantly reduces thermal linear expansion, and provides an oxygen diffusion barrier, making it extremely suitable for radiator panel system installations. These same characteristics also make Alupex excellent for use in conjunction with studded polystyrene insulation panels, for in-screed hydronic underfloor heating systems. With a range of quality fittings available from NTM for use with AluPex multilayer pipe (pictured right), all installation requirements can be covered. Ensure a quick installation with ease, peace of mind and longevity.